Before LOEWER introduced the SwingGrinder in 2009 there were two main methods for deburring laser-cut or punched metal parts. Either this was done manually using power tools or expensive through-feed machines were used. The Original Loewer SwingGrinder bridges the gap between the two and offers the semi-automatic solution.

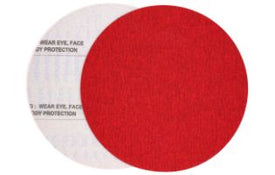

The grinding head consists of two rotating disc tools mounted to a swinging arm equipped with a weight compensation device. This grinding head is guided over the workpiece by hand and grinding pressure is applied manually from above. The inside and outside edges of the workpiece are processed efficiently from all angles and directions. The grinding head can be tilted 180° , thus allowing for speedy switching from a deburring disc to a rounding disc for example.

- Three to four times faster than manual deburring

- Easy-to-use with swinging arm and weight compensation

- High friction table cover, dust drawer and extraction outlet

- Rotatable head with deburring and edge rounding tools

- Numerous safety features including automatic motor shutdown when head is tilted and pneumatic brakes for swinging arm

- For laser-cut, plasma-cut and punched parts

- Processing of foil-covered or zinc-plated parts

- Processing of steel, stainless steel and aluminium